About Us

Company Overview

G6 Materials Corp.

A technology company and world leader in creating value through the development of innovative graphene-based solutions. The Company is strategically focused on serving the global air filtration and purification market with new products to meet growing demand. G6 also sells a range of graphene-based products and other materials, including but not limited to conductive epoxies, high-performance composites and R&D materials, with numerous customers from among the Fortune 500 list of companies, as well as NASA and leading universities.

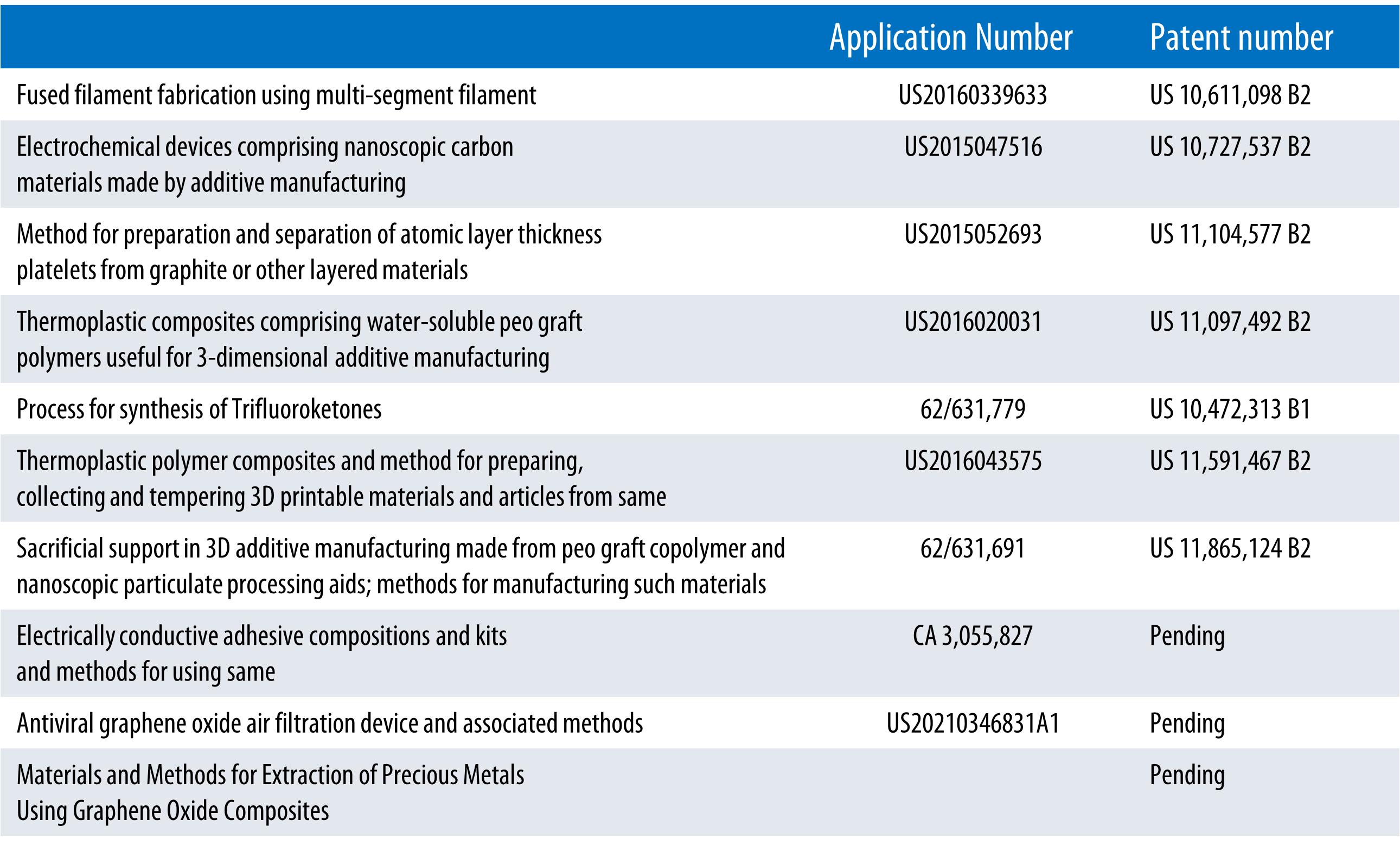

G6 has identified new graphene-based applications to accelerate growth into the future. Accordingly, the Company has a valuable portfolio of intellectual property currently comprising several granted patents and multiple provisional patents, with more patent applications filed.

IP Portfolio

Our Team

Guy Bourgeois - CEO & Director

Gary Dyal - Chairman

Kevin Cornish - CFO & Director

Michael Saxon - Independent Director

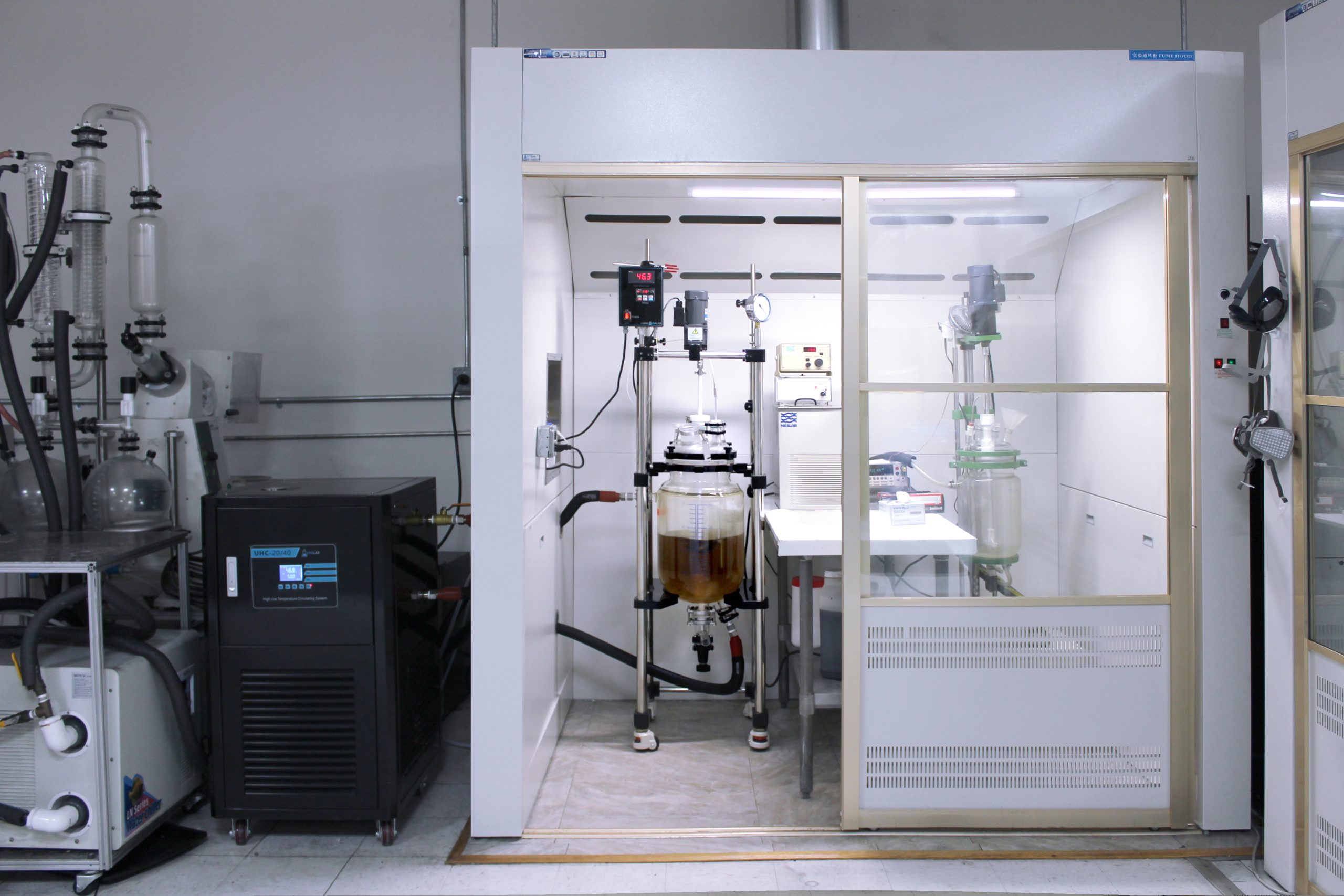

Our Facility

Ronkonkoma Facility

Analytical Laboratory

- Rheology measurement station

- Four-probe conductivity measurement equipment

- Universal test station for evaluation of materials’

- Raman spectroscopy

- Optical microscopy

Manufacturing Plant

Our Technology

Ultralight functional materials

Graphene media for air filtration

Mechanically reinforced resins

Electrical-conductive elastomers

Contact G6 for General Inquiry

Call to Inquire | (516) 382-8649

Investor Line | (866) 324-4244

760 Koehler Ave. Unit 2 |

Ronkonkoma, NY, 11779 | USA

Copyright © 2025 G6 Materials Corp, All Rights Reserved